Classification Of Steel Rail

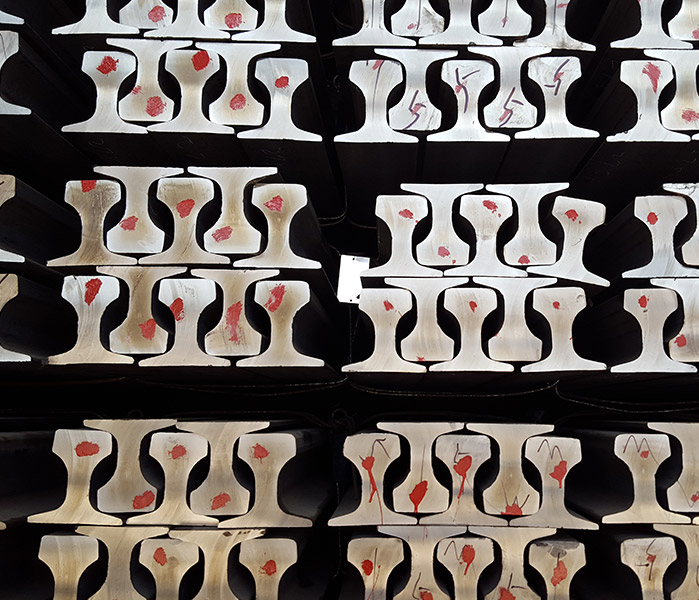

The rails are divided into railway rails, light rails, conductive rails and crane rails according to the Chinese National Standards and the Ministry of Metallurgical Industry.

(1) Railway rails

Low alloy rails have been developed on the basis of carbon steel rails. The high carbon low alloy steel rail has higher strength than the carbon steel rail and has better wear resistance, pressure resistance, brittle fracture resistance and fatigue fracture resistance. Railway rails are available in 38, 43, 50, 60, and 75kg/m.

(2) Light steel rail

Mainly used in mining and forestry, its varieties are 5, 8, 11, 15, 18, 24kg/m. The light rail is mainly made of carbon steel and a small part is made of low alloy steel. Light rails used in mines, underground and forest areas require corrosion resistance. For this purpose, an appropriate amount of alloying elements such as copper, chromium, phosphorus and vanadium are added to the steel.

(3) Conductor rail

Rails used for the conduction of underground railways require good electrical conductivity, ie, a resistivity of less than 0.125μΩ.m at 15°C. It is made of high-quality low carbon aluminum killed steel.

(4) Crane rail

Special section rails for various crane rails have the same chemical composition and manufacturing process as railroad rails. Varieties are QU70 crane rail, QU80 crane rail, QUl00 crane rail, etc.

评论

发表评论