Steelmaking Process (2)

8. Refining period: The process of steelmaking is carried out by slagging and other methods to remove some elements and compounds that are harmful to the quality of steel by chemical reaction into the gas phase or discharged into the slag to remove it from the molten steel. period.

9. Reduction period: In the ordinary power electric arc furnace steelmaking operation, the time from the completion of the slag slag to the tapping is usually called the reduction period.

10. Furnace refining: The steelmaking process of refining the molten steel in the steelmaking furnace (converter, electric furnace, etc.) to another vessel for refining, also called secondary metallurgy. The steelmaking process is therefore divided into two steps: primary refining and refining.

11. Steel liquid agitation: Stirring of molten steel through refining beyond the furnace. It homogenizes the molten steel composition and temperature and boosts metallurgical reactions. Most metallurgical reaction procedures are phase-interfacial responses, and also the speed of diffusion of reactants and products is a limiting measure in these reactions.

12. Ladle feeding cord: spraying the steel tote using deoxidizing, desulfurizing and fine powder coated with iron, like Ca-Si powder, or straight feeding aluminum cable, carbon cord, etc., via the feeding system to greatly desulfurize the stainless steel, iodine therapy and processes for fine-tuning components like aluminum and carbon in steel. Additionally, it has the role of cleaning molten steel and enhancing the morphology of non-metallic inclusions.

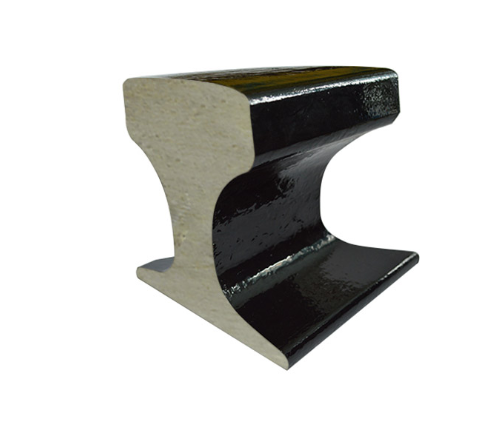

We have 12 Kilogram Steel Rail and 12 Meters Crane Rail exporting all over the world. Welcome to contact us.

评论

发表评论