How Are Steel Rails Installed?

Steel rails are essential components of railway tracks, providing a sturdy, durable foundation for trains to run on. Installing steel rails requires careful planning, precise measurements, and specialized equipment. In this article, we will discuss the steps involved in installing steel rails.

Surveying and preparation

The first step in installing steel rails is to survey the area where the tracks will be laid. This involves measuring the slope of the terrain, identifying any obstacles or potential hazards, and determining the correct placement of the rails. The survey data is used to create a detailed plan for the rail installation.

Once the survey is complete, the site must be prepared for the rail installation. This involves clearing the area of any debris, removing any existing rail, and grading the surface to ensure it is level and stable. Any necessary drainage systems must also be installed at this stage.

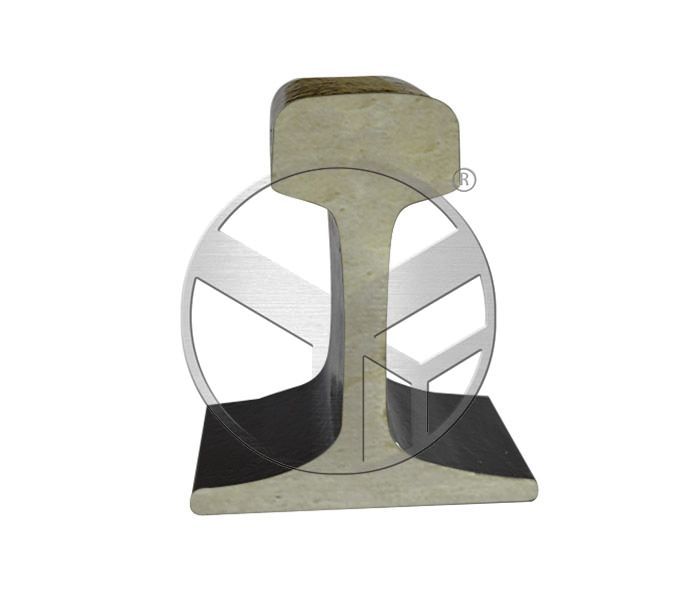

YongYang 75Kg Heavy Steel Rail

Laying the sleepers

The next step is to lay the sleepers, which are the wooden or concrete supports that hold the rails in place. Sleepers are typically placed at regular intervals along the track, and the distance between them is determined by the weight and speed of the trains that will be using the track.

The sleepers are laid out in the correct position, and the spacing between them is measured and marked. The sleepers are then secured to the ground using spikes or screws, and the rails are attached to the sleepers.

Aligning the rails

The rails are aligned using specialized equipment that ensures they are perfectly straight and level. This equipment includes track gauges, which are used to measure the distance between the rails, and track jacks, which are used to adjust the position of the rails.

The rails are carefully positioned on the sleepers, and the track gauges are used to ensure that the distance between the rails is consistent throughout the entire length of the track. The track jacks are then used to adjust the position of the rails, ensuring that they are perfectly aligned and level.

Connecting the rails

Once the rails are aligned, they are connected using rail joints, which are specially designed-connectors that hold the rails together. There are several types of rail joints, including bolted joints, welded joints, and glued joints.

Bolted joints are the most common type of rail joint and are used to connect the rails securely using bolts and nuts. Welded joints are also used, and involve welding the ends of the rails together to form a seamless connection. Glued joints are less common and involve using adhesive to bond the rails together.

YongYang 60kg railway rail china manufacturing

Installing the ballast

The ballast is the layer of crushed rock or gravel that is laid underneath and around the sleepers. The ballast helps to distribute the weight of the trains evenly and provides a stable, durable foundation for the track.

The ballast is laid by pouring it onto the track and using a spreader to distribute it evenly. The ballast is then compacted using specialized equipment, ensuring that it is firmly packed and level.

Tamping and leveling

Once the ballast is installed, the track is tamped and leveled using specialized equipment. Tamping involves using a machine to compact the ballast around the sleepers, ensuring that they are firmly held in place.

Leveling involves using a laser-guided machine to ensure that the rails are perfectly level and straight. This process is essential to ensure that the trains can travel safely and smoothly along the track.

Testing and commissioning

Finally, the track is tested and commissioned to ensure that it is safe and ready for use. This involves conducting a series of tests to ensure that the track meets all safety standards and can support the weight and speed of the trains that will be using it.

评论

发表评论