Daily Maintenance And Maintenance Of The Track

In China, heavy rail and light rail are classified as two independent varieties. The specifications of steel rails (except crane rails or crane rails) are expressed in kg / m, such as 18kg / m, 50kg / m, and so on. Rails weighing less than or equal to 30 kg per metre belong to light rails, and rails weighing more than 30 kg per metre belong to Heavy Steel Rail. To withstand the pressure and impact load of locomotive and vehicle, the rail must have sufficient strength, hardness and toughness, and good welding performance. The rails are also divided into three levels according to the difference in tensile strength. There are three types of ordinary rails, wear-resistant rails and special-grade rails.

Various track maintenance operations to ensure that the track is in good condition and allow the train to run safely, smoothly, and uninterrupted at the prescribed speed. Also called road maintenance. It includes renewal and repair of the track to restore the performance of each component of the track, and prevent and eliminate the regular maintenance work of the track caused by the train's power and other influences.

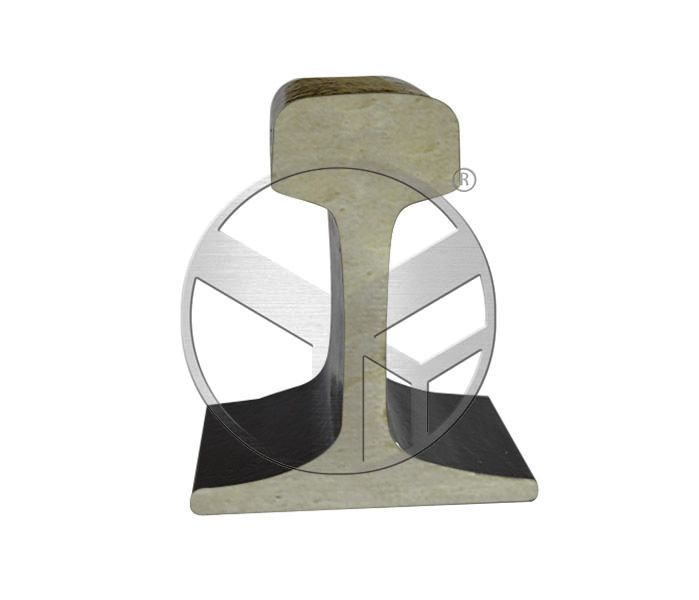

Heavy Steel Rail

In order to ensure driving safety and track components in good condition, to extend the service life of track components, and to avoid economic losses caused by long-term disrepair of track equipment, it is necessary to investigate, formulate and implement maintenance systems to ensure good track conditions. These depend on a variety of factors: the operating conditions of the railway, including capacity, axle weight, speed; the choice of track structure type and the proportion of various lines; the use system, service life, transportation conditions and repair and regeneration capacity of track components; Track maintenance operation system, degree of organization and mechanization, and climatic and environmental conditions.

Track updates include equipment that is replaced with prototypes, as well as equipment that is replaced with heavy equipment. The latter, such as replacing with heavy steel rails, reinforced concrete sleepers, new turnouts, increasing the number of sleeper configurations, and adding paving mattresses. The new track components can be concentrated on the main line, and the replaced track components can be used for the minor lines after being refurbished; they can also be used to replace the old components of other types of lines. Track renewal can be constructed in sections or in sections. The steel rails and sleepers are exchanged individually, and the track bed is partially replenished, often in conjunction with track renovation.

Orbital maintenance is carried out between two orbital renewal periods, and a combination of periodic comprehensive maintenance, sporadic emergency repairs, and inspections and maintenance can be adopted.

Track maintenance work in China is divided into three categories: line overhaul, line repair, and line maintenance. The first two categories are track updates, and the cost comes from overhaul commissions. Line maintenance costs are included in operating costs. Steel Rail Supplier will tell you in detail below.

1. Overhaul of rails is replaced with new or reused rails as the basic content. At the same time, the flat section of the rails is corrected to improve the condition of railroad crossings, so that the quality of the rails is restored to the original standard or a higher standard. There are also single overhauls, including replacement of new steel rails or reused rails in sections, replacement of sleepers in sections, laying, replacement of turnouts and turnouts, and repair of roadbed defects.

2. Line repair. It is mainly for screening and adding ballast, replacing failed sleepers, repairing and replacing failed track components, and repairing the track to restore its quality or close to the original standard.

3. Track maintenance keeps track geometry and track surface smooth. Through track lifting, tamping, diversion, lane change and other operations, track gauge, level, direction, height, etc. can be maintained in good condition for maintenance standards. Components, including replacement of individual damaged and worn parts. Maintenance work also includes line inspections and track status inspections.

The above is the introduction and maintenance of steel rails introduced by Steel Crane Rail Manufacturer.

评论

发表评论